CARDBOARD ECO-WALL

Wednesday, 14 May 2014

Sunday, 11 May 2014

Wednesday, 7 May 2014

CONSTRUCTION DAY VIDEO

THIS VIDEO SHOWS THE CONSTRUCTION PROCESS OF OUR WALL. STARTING FROM WHEN THE MATERIAL PREPERATION WAS DONE UNTIL THE CAMERA RAN OUT OF BATTERY (APPROX 30 MINUTES OUT FROM COMPLETION). IT SHOWS ALL THE PROCESSES AND DECISIONS WHICH WERE MADE ON THE DAY OF CONSTRUCTION.

Monday, 5 May 2014

REFLECTION/

The project was to construct a wall using viable materials being able to last five minutes under a constant on-flow of simulated rainfall. As a group we concluded that we would explore the waterproofing capabilities of cardboard and how this material can be used as a water-harvesting cladding. Naturally, this material presented numerous difficulties, in particular water being typically detrimental to its structural adequacy. Thus the research began. We found that cardboard has successfully been used previously by architects such as Shakiro Ban, where the material is used as an internal cladding or external column. What we really were interested in and did not manage to see reproduced anywhere else was cardboard being used as both an external cladding and a water harvesting material, because naturally, these two don't tend to mix. We sought to find a work-around to this problem and our solution came in the way we were able to keep the cardboard water proof. Upon numerous sealant testings, we found the combined use of generic recycled wax and two coats of clear enamel paint was extremely successful. This combination maintained the structural adequacy of our Eco-wall, rejecting the water flow from the surface under five minutes of simulated rainfall, and a further five minutes of jet stream pressure.

The success of these findings surprised us greatly and validated our months of concept work and testing. As a group, we worked coherently and efficiently, meeting every Tuesday for a de-brief and delegations of tasks for the week, allowing us to finish ahead of schedule. This project has been an enjoyable and valuable experience. We loved the hands on approach and it was great to get away from a screen and physically construct what we had designed. Overall, this project was a success, we designed and constructed an Eco-wall using Cardboard as our material of choice, which we kept water tight, and water smart, capturing rainfall in the cladding, feeding this back to the earth.

Tuesday, 29 April 2014

PROJECT PHOTOS

SUCCESS! OUR WALL DESIGN WAS GREATLY EFFECTIVE IN NOT ONLY REMAINING STRUCTURALLY STABLE AND VIABLE, BUT WAS ABLE TO RESIST THE IMPACT OF WATER OVER MUCH MORE THAN 5 MINUTES WITH NO SIGN OF WATER DAMAGE AT ALL!

PROJECT PHOTOS

JUST A BIT OF FUN.. JAMES' RABBIT 'BRONSON' TESTING OUT THE ECO-WALL. ITS SAFE TO SAY HE LOVED IT!

PROJECT PHOTOS

CLOSE UP IMAGE OF THE FINISHED, SEALED WALL DESIGN. THE WINDOW FRAMING HAS ALSO BEEN TURNED-DOWN TO PREVENT WALTER FROM POOLING AROUND THE SILL

PROJECT PHOTOS

JAMES DRILLING THE HOLE FOR WATER TO DRAIN THROUGH THE DOWN-PIPE BENEATH. THIS WATER THEN RUNS INTO THE GARDEN BED.

PROJECT PHOTOS

APPLYING OUR INTERIOR WAXED-CARDBOARD INTERIOR CLADDING. THIS WAS GLUED TO THE CARDBOARD TUBE FRAME

PROJECT PHOTOS

CLOSE-UP SHOWING THE BOTTOM PLATE AND CARDBOARD STUD, THESE WERE CUT TO ALLOW THE CURVED FACE OF THE TUBES TO INTERLOCK.

PROJECT PHOTOS

THE IMAGE ABOVE SHOWS OUR CARDBOARD FRAME FIXED TO THE EXTERNAL CLADDING SYSTEM. OUR WINDOW IS ALSO IN PLACE.

PROJECT PHOTOS

FILLING EVERY SECOND TUBE WITH EARTH. A GROUP EFFORT MAKING SURE THIS WAS COMPACTED IN ORDER TO BE EFFECTIVE

PROJECT PHOTOS

WE DECIDED TO INSULATE EVERY SECOND TUBE OF THIS EXTERNAL CLADDING SYSTEM WITH EARTH, CREATING AN EFFECTIVE THERMAL BARRIER BETWEEN INSIDE AND OUTSIDE. THE INSIDE OF THESE CUT TUBES HAVE BEEN WAXED, AND THEN COATED WITH TWO LAYERS OF ENAMEL TO PREVENT WATER HELD FROM THE EARTH SEEPING INTO THE INSIDE WALL.

PROJECT PHOTOS

PLACING OUR CUT GUTTER INTO PLACE, DIRECTLY ABOVE THE TOP OF THE SEMI CIRCLE TUBES. WE DECIDED TO RE-USE THE RED CAPS PROVIDED WITH THESE TUBES AS END STOPS TO OUR GUTTER.

PROJECT PHOTOS

FINISHED PRODUCT: WAXED INTERIOR OF OUR EXTERNAL CLADDING. THIS ACTS AS ANOTHER LAYER OF WATER PROTECTION, AND HARVEST WATER FROM THE GUTTER ABOVE, DIRECTING ALL RAIN WATER TO THE PLANTS BENEATH

Wednesday, 23 April 2014

PROJECT VIDEO

SEALING OUR SHINGLE ROOF WITH 2 COATS OF CLEAR ENAMEL

PROJECT PHOTOS

SEALING OUR CARDBOARD ROOF WITH 2 COATS OF CLEAR ENAMEL. THIS METHOD PROVED TO BE VERY EFFECTIVE IN WATERPROOFING OUR CARDBOARD PIECES.

PROJECT PHOTOS

JOSH MATERIAL TESTING THE STRENGTH OF HOT GLUE AS A BINDING AGENT TO OUR CARDBOARD SECTIONS

PROJECT PHOTOS

JAMES RECYCLING THE OLD WAX FROM HIS SURFBOARD. THIS WAS TO BE EFFECTIVELY RE-PURPOSED AS OUR WATER PROOFING SEALANT.

Friday, 18 April 2014

MATERIAL TESTING:

AS YOU CAN SEE IN THIS VIDEO, THE VAPOR DROPS EASILY SLIDE OFF OUR SEALED CARDBOARD ECO-WALL, AND NOT WATER HAS SEEPED THROUGH TO THE OTHER SIDE. SUCCESS!

MATERIAL TESTING:

AS YOU CAN SEE, THE VAPOR BARRIER CREATED BY 2 COATS OF CLEAR ENAMEL REJECTS THE PERMEATION OF WATER. THE WATER DROPS HOLD SHAPE AND ARE SEPARATED, SO IN END THIS IS DEFINITELY A SUCCESSFUL METHOD OF WATER-PROOFING OUR CARDBOARD WALL.

MATERIAL TESTING:

AN ALTERNATIVE SEALANT OPTION IS TO USE A CLEAR, SPRAY ON ENAMEL PAINT. THIS SOLUTION IS NOT ONLY COST EFFECTIVE, BUT IS ALSO EASILY APPLICABLE AND RE-COATABLE ENSURING THE LONGEVITY OF OUR CARDBOARD ECO- WALL.

SEALANT

ANOTHER VIABLE SEALANT SOLUTION IS THE EVERY DAY DULUX WEATHER SHIELD PAINT. THESE PAINTS ARE READILY AVAILABLE AND HOLD THE PROPERTIES REQUIRED FOR A LONG TERM SOLUTION TO KEEPING OUR CARDBOARD ECO-WALL WATER TIGHT. THIS 2PAC POLYURETHANE PAINT NOT ONLY RESISTS THE PRECIPITATION OF WATER, BUT ALSO PROTECTS AGAINST UV BUCKLING OF THE CARDBOARD, AND RESISTS THE BUILD UP OF DIRT. BEING RELATIVELY CHEAP AND EASY TO APPLY VIA PAINT BRUSH, THIS OPTION IS DEFINITELY VIABLE FOR OUR GROUP TO CONSIDER IN THE CONSTRUCTION OF OUR WALL.

Image resource:

http://www.bunnings.co.nz/dulux-weathershield-x10-low-sheen-ultra-deep-base-4l_p00356430

18/04/2014

Tuesday, 25 March 2014

FOR THE DOWN PIPE CONCEPT, WE BELIEVE THAT CARDBOARD POSTAL TUBES WOULD BE SUIT THE FUNCTION WE REQUIRE. THE AUSTRALIAN POST WEBSITE LISTS THREE SIZES OF TUBES AS DEPICTED ABOVE. TO BEST REPLICATE A DOWN PIPES, VISUALLY AND IN TERMS OF FUNCTION, MAILING TUBE Tu2 OR MAILING TUBE Tu3 WOULD BE MOST SUITABLE FOR THIS APPLICATION.

Sunday, 23 March 2014

Wednesday, 19 March 2014

FOR THE BASE

OF THE WALL, WE ARE USING A TIMBER SHIPPING PALLET. THROUGH THE TRANSPORTATION

OF MOVING CONSUMER ITEMS TO DISTRIBUTERS, A SIGNIFICANT AMOUNT OF THESE PALLETS

WILL BE CRUSHED AND DISCARDED AS A CONSEQUENCE. FOR EVERY ONE TONNE OF PRODUCT

THAT REACHES US AS CONSUMERS, 30 TONNES OF WASTE IS PRODUCED THROUGH THE

MANUFACTURING AND TRANSPORT PROCESS – ADDITIONALLY, 98% OF THESE PRODUCTS ARE DISCARDED

WITHIN SIX MONTHS.

USUALLY, THESE PRODUCTS ARE TURNED INTO MULCH OR KINDLING

FIREWOOD, HOWEVER, A COMPANY OUT OF DANDENONG SOUTH HAVE BEEN RECONDITIONING

AND REPURPOSING THESE OTHERWISE REDUNDANT PALLETS. WASTE CONVERTERS WILL

‘REPLACE ANY MISSING BOARDS AND LOOSE BOARDS NAILED. WE CAN ALSO PROVIDE YOUR

COMPANY LOGO IF REQUIRED.’

FURTHERMORE,

SHIPPING PALLETS HAVE BEEN RECENTLY BEEN USED FOR DOMESTIC PURPOSES TO CREATE

LOUNGES, TABLES ETC. A GROWING COMMUNITY OF RECYCLERS EVEN HAVE COMPETITIONS TO

DEMONSTRATE THE UNIQUE AND CREATIVE WAYS THEY HAVE REPURPOSED TIMBER PALLETS.

http://wasteconverters.com.au/PalletsandCrates.php 20.03.2014

Tuesday, 18 March 2014

TO CONNECT ELEMENTS OF THE WALL TOGETHER IN A METHOD THAT

IS BOTH STRONG AND WATER PROOF, HOT GLUE PROVIDES A VIABLE SOLUTION. SIMILAR TO

THE SURFBOARD WAX, THE GLUE CONTAINS RESIN AND WAX, IN COMBINATION WITH ETHYLENE VINYL ACETATE AND VARIOUS POLYAMIDES.

THE HOT GLUE STICKS ARE A

FORM OF THERMOPLASTIC, WHICH REFERS TO A MATERIAL THAT WHEN HEATED ABOVE A

SPECIFIC TEMPERATURE, IT BECOMES PLIABLE AND THEN RETURNS TO A SOLID STATE WHEN

COOL. HOWEVER, WHEN FROZEN, IT EXHIBITS SIMILAR PROPERTIES TO GLASS, BECOMES

FRAGILE AND CAN SHATTER. OTHER EXAMPLES OF THERMOPLASTICS INCLUDE CONTACT

LENSES, PLEXIGLASS, PLASTIC FURNITURE AND CAN EVEN BE FOUND IN SOME WALL PAINTS.

THIS TYPE OF PLASTIC CAN BE

REHEATED, AND SUBSEQUENTLY RESHAPED, WHICH ALSO MEANS THIS MATERIAL CAN BE

RECYCLED.

http://www.globalspec.com/learnmore/materials_chemicals_adhesives/plastics_elastomers_polymers/thermoplastics_thermoplastic_resins

18.03.2014

18.03.2014

Monday, 17 March 2014

Sunday, 16 March 2014

16.03.2014 - http://www.wikihow.com/Make-Surf-Wax

Tuesday, 11 March 2014

WAXED

CARDBOARD IS A TYPE OF CORRUGATED CARDBOARD THAT IS LINED WITH POLYETHYLENE,

IT’S RARELY USED BY CONSUMERS AND IS FAVOURED BY RETAILERS FOR SHIPPING PRODUCE

TO PREVENT MOULD

CONTAMINATION AND INSECT INFESTATION

RECYCLING PLANTS CAN’T RECYCLE WAXED CARDBOARD LIKE THE RECYCLING

PROCESS OF REGULAR CARDBOARD OR PAPER – THIS IS DUE TO THE POLYETHYLENE COATING

AS A RESULT OF THIS PRODUCT BEING USED COMMERCIALLY FOR SHIPPING

PRODUCE AND THE INABILITY TO BE RECYCLED, THERE ARE LARGE QUANTITIES ENTERING

LAND FILL SITES.

THE CONCEPT OF USING THIS PRODUCT TO PRODUCE A WALL FOR WEATHER

RESISTANCE PURPOSES COULD EXTEND THE PRODUCT LIFE CYCLE

Monday, 10 March 2014

REFINEMENT/

THIS IMAGE DEPICTS THE WALL/BASE JUNCTION. THE WALL WILL SIT FLUSH TO THE EDGE OF OUR TIMBER PALATE AND WILL BE PROPPED UP ON EACH SIDE USING TIMBER MEMBERS AS SUPPORT.

Monday, 3 March 2014

RESEARCH/

HERE'S A SADLY COMICAL YET COOL WAY TO USE CARDBOARD, COMBINED WITH WATERPROOFING AGENTS TO PROVIDE A SWIMMING POOL. WE CAN INVESTIGATE THIS METHOD OF WATER PROOFING FOR OUR CARDBOARD WALL. IT GOES TO SHOW THAT CARDBOARD CAN ALSO BE USED TO HOLD WATER, AS WELL AS KEEP IT OUT ENJOY..

http://www.youtube.com/watch?v=CsAxyxDOAS0

RESEARCH/

AFTER DOING SOME RESEARCH ON THIS "NEVER WET" PRODUCT I FOUND IT TO NOT BE VERY PRACTICAL ON A WALL AS IT WOULDN'T LAST MORE THAN AN ENTIRE DAY... (EVEN THOUGH ITS ONLY 5 MINUTES FOR THIS PROJECT, IT WOULDN'T BE WISE TO GO WITH IT) DESPITE THAT FACT, IT IS STILL A COOL CONCEPT SO ENJOY...

Never Wet Superhydrophbic Spray-on Coating

RESEARCH/

CYLINDRICAL STRUCTURES WHERE EVEN CONSTRUCTED BY INDIGENOUS CULTURES USING BAMBOO TO CREATE BASIC FRAMES. WE SHOULD TAKE THIS SIMILAR APPROACH BUT INSTEAD USING CARDBOARD. ANOTHER GOOD IDEA IS THE FACT THEY WERE BUILT ON RAISED PLATFORMS TO HELP PROTECT FROM RAIN AND FLOODING... THIS PRINCIPLE SHOULD BE ADOPTED INTO OUR WALL AND WE COULD USE A PALLET.

Google: Aboriginal building methods

http://australia.gov.au/about-australia/australian-story/austn-indigenous-architecture

CONCEPT SKETCHING/

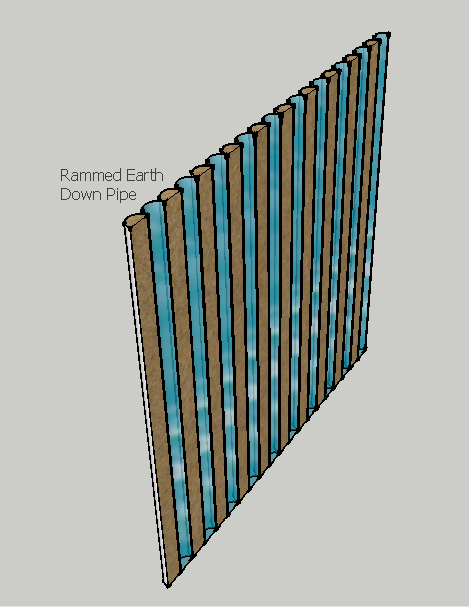

EVERY SECOND CARDBOARD TUBE CAN BE FILLED WITH RAMMED EARTH TO ADD TO BOTH THE STRUCTURAL INTEGRITY OF THE WALL AND ANOTHER LAYER OF THERMAL MASS. AS RAMMED EARTH CAN BE CONSTRUCTED ON-SITE IT WILL BE EASY TO ACCOMPLISH WITH MINIMAL TRANSPORT AND TIME COSTS. BEING SOURCED FROM THE GROUND IT IS VULNERABLE TO WATER DAMAGE, SO WE WILL NEED TO MAKE SURE TO PROPERLY WATER PROOF THE INTENDED TUBES IF WE TAKE THIS APPROACH.

RESEARCH/

LOOKING CLOSELY, WE HAVE A LOT TO LEARN FROM THE SIMPLE CONSTRUCTION OF THE BIKE FRAME. IN THIS DETAIL WE CAN SEE HOW TWO CYLINDRICAL COMPONENTS HAVE BEEN INSERTED INTO EACH OTHER AND THEN FIXED, CREATING A STRUCTURE. WE CAN APPLY THIS METHOD OF THINKING AND PRACTICE TOWARDS OUR CARDBOARD TUBE FRAME WALL. WE WILL NEED TO INTERLOCK THE COMPONENTS OF THE WALL JUST LIKE THIS BIKE FRAME DETAIL.

https://www.google.com.au/search?q=hENRY+jAMES+bICYCLES&source=lnms&tbm=isch&sa=X&ei=LBcVU4SVDKT_iAf9h4HQDg&ved=0CAcQ_AUoAQ&biw=1366&bih=624#q=tube+bike+frame+detail&tbm=isch&facrc=_&imgdii=_&imgrc=UUjgBj824iJtWM%253A%3BQbmGjjJwWP2suM%3Bhttp%253A%252F%252Fgeorgenaterry.com%252Fwp-content%252Fuploads%252F2012%252F12%252FKeynoteScreenSnapz001.jpg%3Bhttp%253A%252F%252Fgeorgenaterry.com%252Ftriaxial-tension%252F%3B585%3B442

Subscribe to:

Comments (Atom)